Improving Business Results with Reliability Management

It is no secret that customer satisfaction starts by using, operating a reliable product, a product which allows the customer to comply and exceed his duties. So, investing in managing the product reliability you will make sure that the product allows your customer to succeed. By doing this you are creating an environment for loyalty, which naturally brings more revenues and better business results.

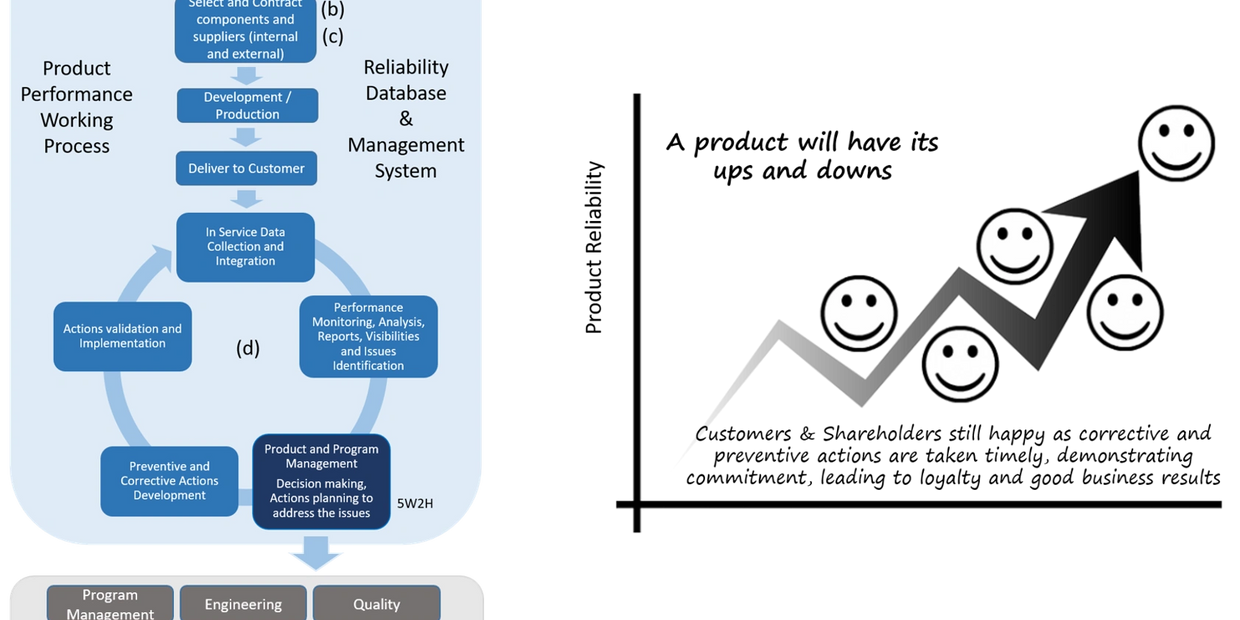

One thing is to say that the company recognizes the importance of the subject; the other thing is to translate into processes, policies, and mindset.

Let me list here important aspects when we decide to manage product reliability.

a. Understand and define the reliability requirements and targets of the product. The definition must come from the market, understanding customer needs, if possible, coming from customer mouth. Once are determined, they flow down to tech specs, development and management processes.

b. Most of products and components are made of piece parts, so it is important to look for the high quality ones (proven real life results) and which the OEMs will back them up should a problem occur. Procuring and contracting according to specs is an important step even when producing internally. During development programs like HASS (high accelerated stress screening) and HALT (highly accelerated life test) might be used depending on the complexity of the development, the environment the product will be operating and spec requirements.

c. The reliability targets and remedial actions are fundamental on contracting. Should you fail to have this step properly done, the in service phase will be tough as nothing goes 100% according to spec. Most of in service issues will fall into the gray zone, meaning split responsibilities between the company and the manufacturer of the piece part or component purchased to be part of your product.

d. During regular operation, with the product in service, you need to monitor its reliability. What do we need here?

- Data from the operation, meaning you need to create a process, which the data from the replacement and repair of the components are collected and registered such as reason for the replacement and any data which could support a fault analysis and tear down analysis, when the component is repaired, indicating which actually failed and why.

- It is easy to understand that you need a database, integrated with your data sources, and a reliability management system, which will allow you to have a picture of the situation, comparing targets versus actuals, trends, probable causes and consequences. Depending of the situation even if you do not have the cause yet identified you might need to deal with the consequence and take actions to prevent failures to continuing occurring.

- At this moment, you need to have a team of specialists involved, depending on the size of your company, on top of the customer support people, your engineering department, quality team, production, program management, suppliers.

- To be able to coordinate well all these players comprehensive process, procedures and policies need to be in place. What, when, why, where, how, how much to do will be in the day-to-day activities and if not well-managed may affect your business results and worst, your customer trust on your ability to isolate his operation from the product issues.

- A full PDCA cycle will be happening at this stage. How serious and committed you will do it will determine your chances to excel with the customers.

- All data collected like issues, causes, consequences, preventive and corrective actions will feedback the current programs in development or the ones still to be developed guaranteeing that such type of issues won’t happen in other products or programs (lessons learned process and database).

- In more complex products a program called PHM (Product Health Monitoring) can also be used, allowing predictive, preventive and corrective actions be applied on the best time optimizing the operation for less risks, impacts and costs with higher product availability/reliability.

- It’s worth mentioning that, although is not exactly part of a Reliability Management, but as important, is the obsolescence of the product which deserves attention too. We will develop this subject in a future article.

Maintain constantly your product reliability on target levels will not be easy and will demand attention, resources that shall be already planned on the product BP.

Why do you have to do all this?

Although it might sound obvious, let’s make sure everybody is on the same page:

- Your business plan is based on an expected product performance

- If the performance is not achieved you will be forced to put your efforts to recover.

- Depending on the business you are in and the product you sell, such effort might be:

o Redevelopment costs

o Extra repair and warranty costs

o Extra production costs

o Extra customers costs depending on the situation

- Impact on your customer operation/duties and naturally on his satisfaction which might reflect in different ways:

o Extra effort to keep his account

o Extra effort to recover his trust

o Loose his trust and his future purchases

o Impacts on your reputation which will impact your new sales campaigns

- Since you planned well and you understand the importance of maintaining product performance; the first group can be manageable. This last group of impacts are the ones, which really can harm your business to an uncontrolled way, so definitely you do not want this to happen.

- The longer you wait to react the more costly and riskier will be as your production will still be producing the same product to the market which will need fixes later.

You might even have issues with your product, and your customer knows that will happen. What really matters is how you deal with them. That will be paramount to your customer loyalty to you.

If you excel in managing your product reliability and the way you support, you will have more opportunities to optimize your entire operation and certainly have good business results.

Nov 2018

Product Reliability Management, one important pillar to excel with customers

Martini Consulting will help build the processes which will lead to a strong product life management.

Martini Consulting Ltda

Rua Oscar Coelho Laurino 109, São José Dos Campos, SP 12244-840, BR

Política de cookies

Este site usa cookies. Ao continuar a usando-o, você estará concordando com nosso uso de cookies.

This site uses cookies. By continuing to use it, you are agreeing to our use of cookies.